Printers are the most popular consumable device that most people use, there are benefits and disadvantages of having the different kinds of printer, which I will discuss as well as common problems that people have with them. So let’s get started…

Inkjet printers

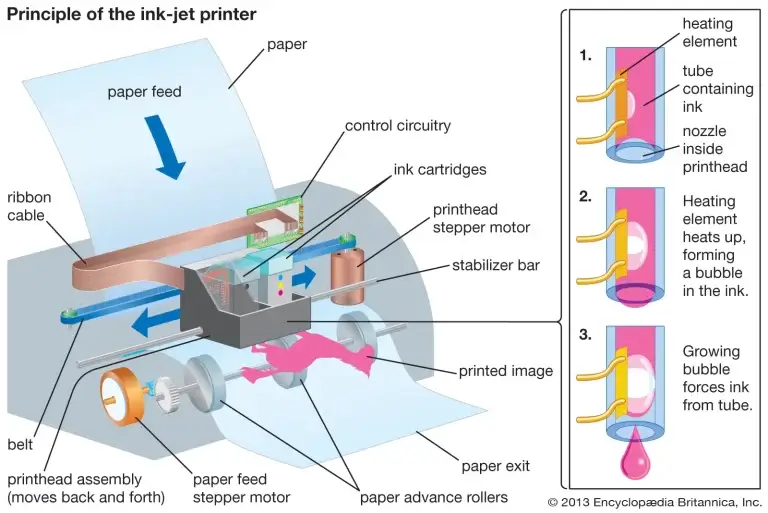

Inkjet printers (known as drop on demand or DOD printers in industry, to differentiate from Continuous Ink Jet) are largely separated into two types:

- Thermal drop on demand – These are commonly developed by Canon, HP and Lexmark where a heater causes a droplet of ink to leave the print head and is forced out onto the paper. The print head and cartridge are in one piece, so when the head fouls, the head is replaced when the cartridge is replaced.

- Piezoelectric drop on demand – These are commonly developed by Epson and Brother, however HP does have this kind of printer in use occasionally. A piezoelectric crystal is charged and flexes to draw a drop of ink up and then discharged to drop the ink onto the paper. These printers have a separate print head to the cartridge which makes them cheaper to replace the cartridge.

The biggest downside to an piezoelectric inkjet printer comes when the user removes the cartridge and takes it to a shop for refilling, the ink can dry in the tubes of the print head.

Ink Tank printers

Ink Tank printers are a piezoelectric print head attached to tanks instead of cartridges to offer a higher yield as well as a method to see how much ink is left in each tank.

Ink tank printers offer cheaper ink bottles but have the same problem as all ink jet printers, in that if they are not used for a period of time, the ink will dry in the print head and then become useless.

Print head cleaning

The manufacturer has a method of cleaning the printhead which often involves wiping the head over a rubber pad until the dried ink is removed from the surface while attempting to eject ink through the head.

You can purchase different kinds of head cleaning solutions, these require a syringe and tube as well as blotting paper which you need to cut into strips and place under the carriage. Slowly and gently inject the solution into each ink port of the printhead and you can leave this overnight to dissolve stubborn ink. You then remove the ink covered blotting paper.

You then need to replace the cartridges and run a head clean and nozzle check a couple of times. If the process does not produce the desired result, try the process again.

Do not be tempted to use acetone to dissolve ink from the printer as acetone is a solvent that dissolves plastic and you will have a much bigger problem on your hands.

DIY print head cleaners are often 80% ammonia window cleaner (based on a 5% ammonia solution) and 20% isopropyl alcohol.

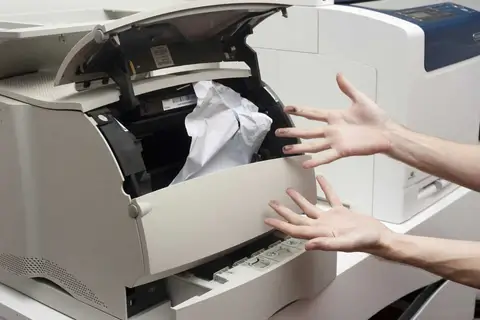

Paper jams

Paper jams can occur with printers when the paper doesn’t load properly or the rollers have become dirty. Often the paper is loaded by human error but the result can be difficult to clear.

This is also hampered by the fact the motor in printers is not designed to run backwards, so jams get worse with the printer operation.

You will need a strong light source to locate the source of the jam and then use plastic tools to push or lever the jam out of the way. You may find thicker paper or card will work to move a jam from the printer.

You can clean the rollers with a lint free cloth and water, then wipe the rollers with a dry cloth.

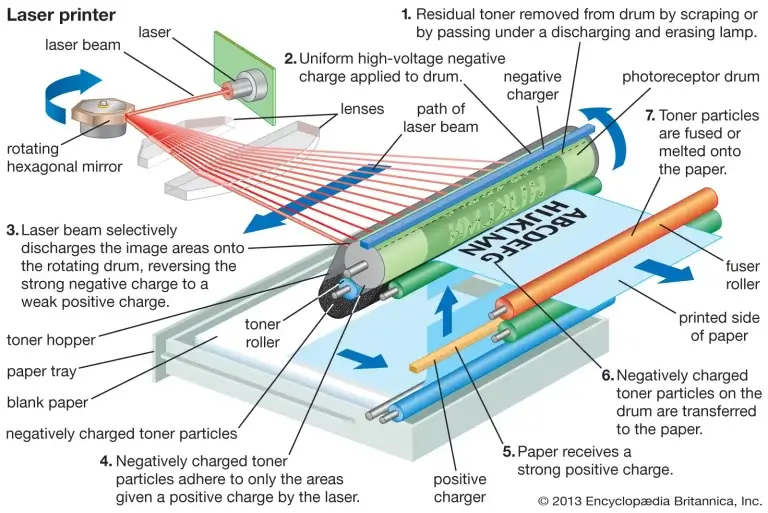

Laser printers

Laser printers don’t use a laser to burn the paper, instead they use the laser diode to charge the paper with static so that toner (which is really just tiny particles of plastic) gets drawn to the paper and then a heater (called a fuser) bonds the toner to the paper.

In a colour laser, there are multiple different colour toner cartridges that the paper passes over to give different colours.

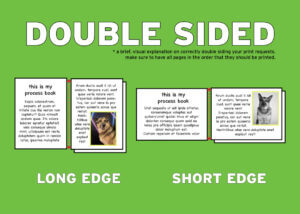

Duplex printing

Duplex or double sided printing involves printing on both sides of the paper. The printer cannot do this simultaneously, it has to either require the user to flip the pages over (called manual duplex) or to use rollers to flip the page (automatic duplex.)

If you need to print two documents double sided so that each page has the other document on the back (say a book with drawings on the other page) you can do this by printing both documents as PDF then:

- Open the first PDF in PDFill Tools.

- Choose Convert PDF to Images

- Open the second PDF in PDFill Tools.

- Choose Convert PDF to Images.

- Choose Convert Images to PDF.

- Pick the images alternately from the first and second document.

- Print out the resultant PDF.

Printing white

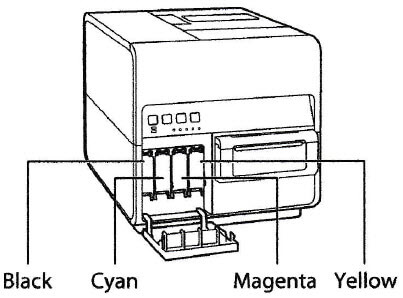

Printing is an additive process where 4 secondary colours are used to create every shade of colour using cyan, magenta, yellow and black (CMYK) on white paper.

However, if you don’t load white paper, you will not get white.

White toner cartridges are available, but you simply replace the black cartridge with white and then you can’t print black, which is fine on dark paper.

Sublimation ink and toner

There are sublimation inks and toner for printing on polyester surfaces. The printing process is similar to normal printing (be it inkjet or laser) but the ink is sublimated (turns into a gas) when heat is applied.

However, white toner does not work on black polyester so there is no white sublimation toner or ink.

Compared to transfer printing (where you print to transfer paper then to textiles) the design is embedded into the fabric of the garment rather than on the surface. The designs can be stretched without damaging the design, as it is part of the garment.