When I went to college, I initially studied electronics and obtained a City & Guilds in Electronics Servicing along with a BTEC in Electronics, later switching to Computing. The components back then were called discrete, meaning they had a single role.

Transistors

Transistors had their roots in triode valves. Just like triode valves, they could be used as switches and as amplifiers, because you supply a small voltage on one side and on the other, that voltage is amplified.

Valves had the disadvantage of requiring a large power supply and were bulky whereas transistors don’t require much power and can be compact. This lead to the creation of the transistor radio, since small and light components made it possible to create portable radios cheaply.

There are different kinds of transistor depending on it’s use.

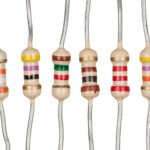

Resistors

Resistors restrict the flow of electricity, and therefore lower voltages passed through them, they do that by dissipating the energy as heat. Resistance is measured in Ohms, and the coloured bands tell the user how resistant the resistor is.

The element in your kettle is a resistor. It turns electricity into heat and boils water.

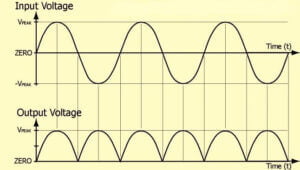

Diode

A diode only allows electricity to flow one way. This makes them extremely useful if the power input could accidentally be reversed.

A LED or Light Emitting Diode, is a diode that releases light when electricity flows one way. An RGB LED has 3 LEDs mounted inside the plastic casing, so that when electricity flows in different directions, it can illuminate red, green and blue, and flickering through those colours can give the illusion of showing any colour.

A so called “flywheel” diode is used with a relay or motor to protect electronics. A relay is an inductor that creates a magnetic field which opens or closes connectors on the other side of it. A motor is also an inductor that creates a magnetic field that causes the axle to spin. When either of these are switched off, they need somewhere to release the energy to, and the flywheel diode provides that release.

A bridge rectifier uses the properties of diodes in a set configuration to turn an AC into DC but doesn’t produce a smooth DC voltage, it requires a capacitor to smooth out the peaks and troughs.

Capacitors

Capacitors store energy. They allow AC to pass through them, but block DC.

Capacitors are used to smooth DC power. They charge on the up side of the increasing voltage, then slowly discharge on the falling side, releasing their electricity to prevent the curve dropping to zero.

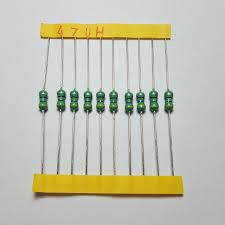

Inductor

Inductors, like capacitors store energy, but they allow DC to pass through them but block AC by converting it into mechanical energ. You can find them in power circuits to make sure the power supplied to a regulator is DC and not AC.

Inductors are used in DC circuits where a large starting current is needed, such as with a DC motor. The inductor prevents the circuit breaker from arcing when the circuit is joined or broken. It’s called a soft start.

A transformer is a type of inductor, converting AC into magnetic energy and transmitting that energy to another coil that can be used to increase the current and reduce the voltage (step down) or reduce the current and increase the voltage (step up)

Other discrete components

There are other kinds of discrete components, like varistors which are voltage variable resistors often using in power strips to give appliances surge protection.

Thyristors (also called Silicon Controlled Rectifiers) function like a switch. Unlike transistors, which can be used in amplifiers because they can be used variably, thyristors are either on or off.

A triac (Triode for AC) is a type of thyristor that allows electricity to flow both directions and are used in power control circuits and AC dimmers.

There are also transducers, sensors and detectors.

Integrated circuits

Integrated circuits (ICs) made it possible to complex operations that would take a load of complex discrete components. Discrete components are still used around integrated circuits.

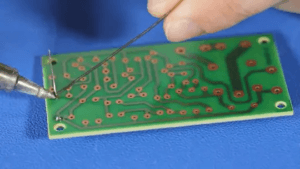

Through-Hole Soldering

Through-hole soldering was the first form of electronic soldering. Components are pushed through a Printed Circuit Board (PCB), then flux is applied and then solder is added when heat is introduced from a soldering iron. Once the joint is soldered, the excess can be cut away using diagonal snips.

Solder used to be an alloy of tin and lead, which had an advantage where tin grows hairs over time, known as dendrites, but the lead caused them to curve back on themselves. However, lead is poisonous, especially as a vapour.

Solder is now Tin, Silver, Copper or Tin, Silver, Copper, Zinc. This has the advantage that there is no poisonous vapours, but the risk of dendrites can still form.

A dry joint can be caused if the solder joint is still moving when the join cools and can cause a component to behave unexpectedly, sometimes like a diode.

Through-Hole Repairs

Using a hot soldering iron and some copper braid, or a suction tool, solder can be removed from a component and the component extracted. The replacement component can be inserted in the hole, a small amount of flux applied and the component can be soldered back into place with some solder and application of the heat from the soldering iron.

Dry joints can also be repaired by reheating the joint, or removing the old solder and soldering new solder in it’s place.

A broken track can be patched around using thin jumper wire soldered from one pad to another. Sometimes a pad or track can peel off the fibreglass, it will need to be cut to prevent it peeling further and a patch wire used to fix the damage.

Multilayer PCB

I used to make my own boards at one time, I’ve done it twice in the past.

- Design the board using PCB software and copy the design onto acetate sheet.

- Stick to the copper coated fibreglass board and expose the board to UV light.

- A developer is applied to the board, this changes the colour of the parts that weren’t exposed to UV light.

- The board is placed in an etching solution to dissolved the UV exposed copper.

- The board is washed with isopropyl alcohol or acetone and then a treatment is added which protects the copper form oxidising. This gives the board it’s green colour.

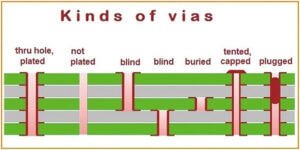

Mass manufactured boards are made using a similar process, but the process is much longer as they can develop multi layer boards by gluing the board layers together using epoxy resin and use vias to join the tracks to different layers. Each board has tracks both sides to join components together.

The inner layers of the board don’t tend to get damaged in use, boards are tested before they leave the factory, so any faulty boards are discarded and the copper recovered.

Surface mount

Technology has changed vastly since I was in college, and so has miniaturisation.

With mass production, a board is coated with solder paste and then the board is secured in a pick and place machine which picks components from a roll or a tube and sticks them on the solder paste. The board is then heated using a carefully controlled oven that melts the solder paste and bonds all the components to the board in one go.

Surface mount repairs

Surface mounted components are considerably smaller than discrete components so require different tools. A hot air gun heats the pads quickly so the bad component can be lifted up on one side, then the other sides can be heated until the bad component is removed. Replacing the component involves applying flux to the surface or solder paste and attaching the component on one side. Care must be taken in aligning the pins in exactly the right place.

Care must also be taken when heating boards that have plastic on the reverse side, such as some mobile phones, as replacing the component can break another component on the other side.

Conclusion

With the right skills and components, you can repair most devices that have an electrical problem.

Next time your device breaks, can it be repaired easily? Changing a cheap component vs buying an expensive replacement. There used to be TV engineers that would repair common problems for a small fee.

You can now google the problem you are having, and find out what component is at fault and either repair it yourself, or send it to someone to repair it instead of adding it to the pile of TVs down the tip.